Decanter Centrifuge for muddy juice separation

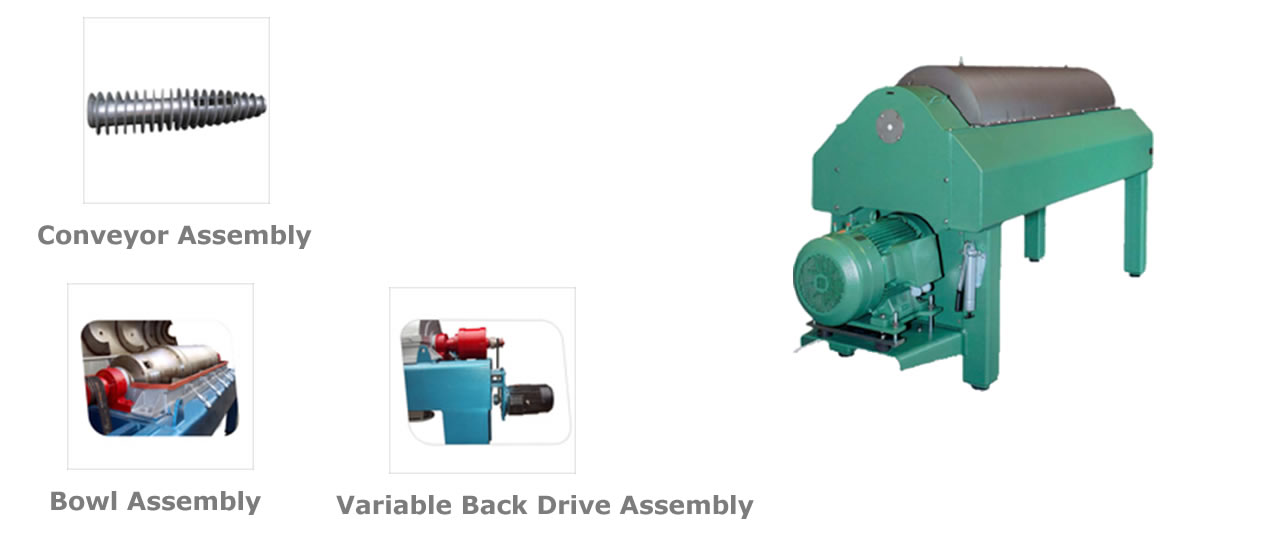

1. Decanter Centrifuge (Solid Liquid Separator)

As we are well known manufacturer, exporter and supplier, we are involved in offering Decanter Centrifuge (Solid Liquid Separator) to our customers. This product is particularly based on horizontal separation technology and work at slow / high speeds. Due to its various designs, lengths and cone geometries, this can be applied in any processing environment that need two or three-phase separation of solids and liquids. In solid base application, our Decanter Centrifuge (Solid Liquid Separator) ensure optimum separation efficiency, specially in the case of suspensions with a very high proportion of solids.

Material Technology

LOVELY PROJECT AND ENGINEERING uses high grade centrifugal cast stainless steel for all parts the come into contact with the process, in order to avoid any risk of the corrosion associated with the uses of carbon steel.

Application :

Sugar factories, Chemical, Pharmaceutical, Oil and Fats

Capacity :

1000 to 25000 LPH

2. Conveyor Assembly:

Catering various industrial demands as manufacturer, exporter and supplier of Conveyor Assembly which is made with standard bearings. This product is used for long assembly line operations like testing, sorting, inspection and packaging. Our entire product is widely used in globe in various industries such as automobile industries, packaging industry, and pharmaceutical industry. Available in different sizes, designs and shapes, this Conveyor Assembly is supplied to our valuable customers in a promised time frame as well as at market leading prices.

Material TechnologyLOVELY PROJECT AND ENGINEERING uses high grade centrifugal cast stainless steel for all parts the come into contact with the process, in order to avoid any risk of the corrosion associated with the uses of carbon steel.

Application : Sugar factories, Chemical, Pharmaceutical, Oil and FatsCapacity : 1000 to 25000 LPH

3. Bowl Assembly:

Leveraging upon our experienced team of professionals, we are able to manufacture, export and supply the premium quality Bowl Assembly. This assembly is designed and manufactured in conformity with the set industrial standard using premium quality components and advance technology. Widely appreciated by large number of customers due to its high quality and durability, this assembly is made according to the specifications provided by the customers. We supply this Bowl Assembly to customers after thorough check so that the quality of our product is maintained.

Bowl Assembly :

- Edible Oil Refining Plants

- Decanter Centrifuge

- High Speed Centrifuge

- Separators

- Filters

- Fish Oil Refining Plants

4. Variable Back Drive Assembly:

We are listed our name among the well known manufacturer, exporter and supplier of highly durable Variable Back Drive Assembly. This product is designed under the guidance of our professionals by using premium grade materials and latest technology. Widely used in various industrial applications, this drive assembly is completely tested under various quality parameters before delivery to our customers. Keeping in mind the budgetary constraint, we offer this Variable Back Drive Assembly to our customers at reasonable rates. Also supply them in a promised time frame.

Material TechnologyLOVELY PROJECT AND ENGINEERING uses high grade centrifugal cast stainless steel for all parts the come into contact with the process, in order to avoid any risk of the corrosion associated with the uses of carbon steel.

Application : Sugar factories, Chemical, Pharmaceutical, Oil and FatsCapacity : 1000 to 25000 LPH